|

ENGINE WITH COMBUSTION

Clean engines for land and sea

transport has low noise, low toxicity and the ability to exhaust the

various fuels.Comparable to the engine size

and weight. All of these options provide an opportunity to challenge

the internal combustion engine.The source of thermal energy

you can use any heat source: solar energy, biofuels, nuclear energy,

electricity and so on.

The challenge underlying the solution is to create a heat

engine with expanded functionality.Namely, first, creating the possibility of

operating the engine in the heat pump, which will in return the

braking energy and store it in a heat accumulator for later use.

Secondly, creating the possibility of starting the engine without a

forced way, which will abandon the starter device and devices turn

off the engine with the clutch mechanism of the executive, as well

as from the engine to operate in Idle Mode.Third, creating the possibility

of rotation of the motor shaft in any direction, which will abandon

the device changes direction of rotation.Together, the rejection of

part of the transmission equipment will improve efficiency and

reduce material devices serviced engine.

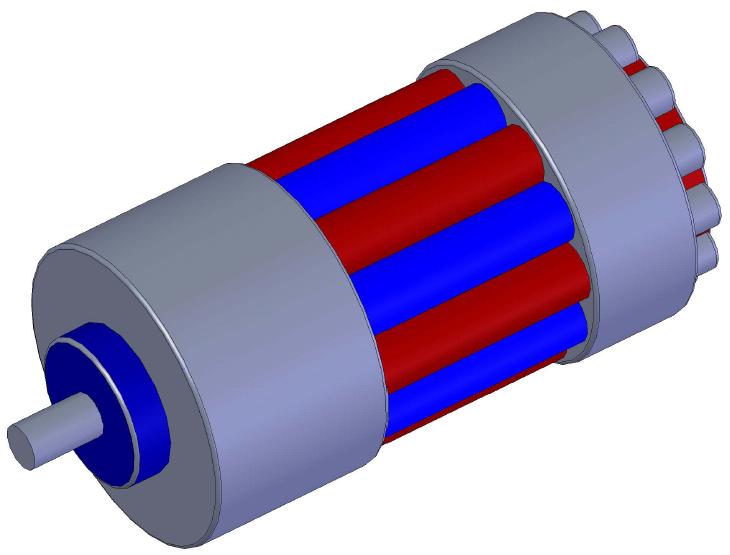

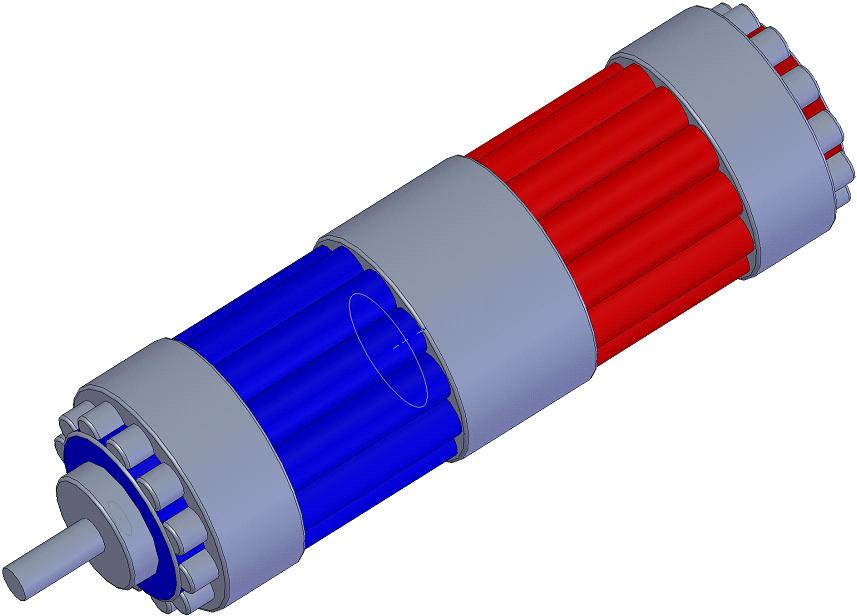

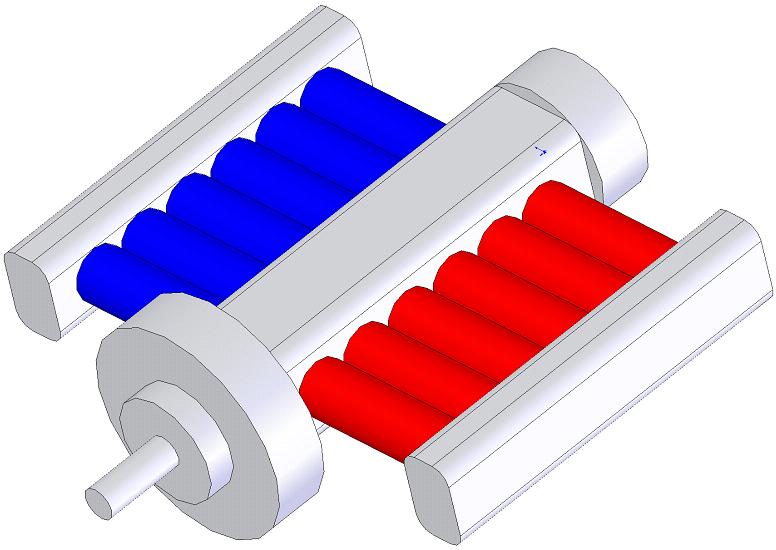

Structurally, the engine has four extensive

and four compression cylinder.The cylinders are alternately and in

parallel around the axis of the working shaft engine.

The mechanism of

conversion of reciprocating motion is made in the form of oblique

washers, as the drive axial-piston pump.Combustion occurs

in the heat exchange chamber.

To heat to the working body through the heat transfer

tubes.When

compressing the working medium is carried out the withdrawal of heat

through heat transfer tubing and cooling the working medium in the

cooler (radiators).Number of gas (they can

be air), a prisoner in a working volume of the engine, continuously

and irremovable. Working the body is under great pressure, the order

of 40-200 atm.

Appearance engine modifications:

The engine is roughly the same size and

weight as an ordinary gasoline engine.

By the features of the proposed engine are:

High KP e. Ability to obtain a high-KP

village and, consequently, a large economy is an important

feature of the engine.

This is due to the full use of differential temperature and

pressure in the cycle.But to

realize these opportunities need to overcome significant design and

technological difficulties, and difficulties in the selection of

materials for the manufacture of engine parts.

Various heat sources. The external supply of heat used in

the engine, allow the use of different heat sources, without any

significant change the engine design.Almost all

fossil fuels from solid to gas can be directly used in the

engine.

To do this, equip the engine combustion chamber with a

regenerative heat exchanger for preheating the air charge heat of

exhaust gases.

In cities with heavy traffic for use in

vehicles has great prospects for the engine to heat the

battery.

The advantage of the engine is

also in that it can be used in a variety of fuels, but also provides

an opportunity to apply various types of heat sources.

This means

that the engine does not depend on the availability of the

atmosphere.It could equally well work in a

confined space, as on submarines, and on satellites.

The impact

on the environment (toxicity, noise, vibration).

Obviously, the toxicity of engine (in

the conventional sense), it is possible to speak only when using the

heat of combustion of fuel.

Sources of toxic substances are

the products of combustion and evaporation of it from the feed

system.The engine works on the closed-loop, so it

is not the crankcase and the combustion products resulting from the

crankcase does not release toxic substances.

Evaporation into the atmosphere in the engine is

much less than that of gasoline internal combustion engines, as well

as the fuel system of closed type.Virtually the only

source of toxic substances - products of combustion out of the

atmosphere from the combustion chamber.

The main toxic

substances contained in products of combustion of such fuels are

carbon monoxide CO, unburned hydrocarbons C x H

y, NO x, nitrogen oxides, aldehydes, soot,

sulfur oxides (using sulfur fuels), lead (for leaded

petrol).

Estimate the toxicity of

the engine on the allocation of carbon monoxide, hydrocarbons,

nitrogen oxides, as well as opacity. the allocation of

available or imposed statutory limitations.Toxic products

of incomplete combustion (CO and C x H y) are

the result of lack of oxygen during the combustion (at small general

or local rates of excess air).

Soot in the

exhaust gases is shown in those cases when the thermal decomposition

of hydrocarbons (cracking) at high temperatures and lack of

oxygen.Cameras combustion engine similar to the

combustion chamber of gas turbine and steam engines.

The process of burning them is

stationary.

In such circumstances, can provide enough high quality of

mixture.The air entering the combustion

chamber, is heated in a special heater exhaust gases.

Obviously, the

selection of toxic substances in exhaust gases into the engine

depends on the coefficient of excess air during combustion and the

temperature of inlet air into the combustion chamber.

With the increase of the coefficient of excess air

during combustion decreases the concentration of CO, C x

H y and NO x.Consideration of

the mass of the toxic components released during the combustion of

unit quantity of fuel, leads to the same conclusion.

It is important to

note a very small concentration of CO, C x H

in. The concentration of NO x decreases with

increasing excess air ratio due to the significant impact of

reducing the temperature compared with the impact of increasing the

number of free oxygen in the combustion products.Because the coefficient

of excess air increases the efficiency of the engine a few drops,

then the rational value of the coefficient of excess air during

combustion is about 1,5-1,8.

With the increase of air temperature entering the combustion

chamber, at a constant ratio of excess air content of products of

incomplete combustion (CO and C x H y) is

decreasing and the concentration of NO x

increases.Efficiency of the engine also increases with

increasing air temperature at the inlet to the combustion

chamber.Reducing the

concentration of CO and C x H a due to

improved conditions of combustion in a hot air.Increased

concentrations of NO x caused by the increase in the

maximum temperature of combustion at a constant ratio of excess

air.

Inlet air temperature in the combustion chamber in the engine

reaches 600-800 В° C.

It should be noted that the engine

exhaust gases have no smell and does not contain carbon

black.

The above material shows that the greatest

impact on emissions of nitrogen oxides have a motor. The allocation

might be reduced by exposure to conditions in the combustion chamber

(the maximum decrease in temperature and oxygen

concentration).To lower the

temperature in the combustion zone by selecting the appropriate

parameters of the combustion chamber or use exhaust gas

recirculation (as in internal combustion engines).

Increasing the number

of perepuskaemyh exhaust more than 33% of the number of

incoming fresh air is not feasible, as this significantly increases

the concentration of CO and NO x concentration decreases

less significantly.

To assess the level of

toxicity in the table below shows the engine unit of toxic

substances in the engine, the diesel engine, gas turbine and

the gasoline engine.

|

Engine type |

Toxic constituents in

mg / (bhp c) |

|

NO x |

CO |

C x H

in |

| Engine DVPT |

0,1-0,2 |

0,05-0,2 |

0,0015-0,009 |

| Gas turbines (with

regenerator) |

0,7-2,0 |

2,0-3,6 |

0,0120-0,072 |

|

Diesel |

0,4-2,0 |

0.2-5,0 |

0,6-12 |

| Petrol engines |

0,6-2,0 |

40-100 |

15-120 |

From the

table it follows that even without the adoption of special measures,

the toxicity of engine exhaust gas is significantly lower toxicity

of other types of heat engines.

Low noise and vibration.

The main sources of noise in internal combustion engines are turbo,

the combustion process, the processes of intake and exhaust

timing mechanism, crank, connecting rods and the support mechanisms

(due to the presence of gaps in the toothing, occasionally

overlapping gaps in the joints and movable etc.).Noise generation mechanisms in the auxiliary

engines of the internal and external combustion can take the same,

other sources of noise in the engine are not available, so the noise

from the engine is running, much less than the internal combustion

engine.External combustion in the engine occurs

continuously and does not have an explosive character, which, when

burned, and release almost no noise is generated.

In addition, the pressure in

the cylinders of the engine varies smoothly on almost sinusoidal

law.The noise level of the engine at an average

of 20-30 dB lower than the diesel engine is the same

power.

Consumption of lubricating oil. In

internal combustion engines hit the oil in the cylinder, on the

one hand, leads to the burning of oil, on the other hand, due to

its aging contact with hot gases and engine parts.

The proposed engine oil practically

can not get into the working cavity and, moreover, did not come with

any hot gases or the hot parts, so not happening either burnout or

osmoleniya oil.As a result, the engine is no longer necessary

to periodically adding oil.In principle,

the engine can develop throughout motoresursa initially filled with

oil (if time does not change its properties under the influence of

the environment), which is cleared only on the abrasive

particles.For the heavy-and medium-power is an

important economic advantage (cost of lubricating oil is 10 times

higher than the cost of fuel).For low-power engines that significantly

reduces labor services.

Release of oil in the

engine working conditions is extremely undesirable and extremely

damaging phenomenon, as well as changing the properties of gas and,

consequently, the effective efficiency of the

engine.Therefore, in the engine are not lubricate

the piston rings, and lubricant is required only to lubricate the

drive mechanism and support units.As the piston seals in the engine used

continuous ring of fluoroplastic or composite materials based on the

latter.

Reliable and fast

start-up of the engine at low temperatures. The proposed engine

with high pressure of gas in the inner cavities and sufficiently

high temperature heater tubes, easy starts at any temperature

environment. His start-up depends entirely on the reliability, which

may ignite the fuel in the chamber combustion.Spark

plugs, which merged with the nozzle in a single whole, virtually

guarantees the start-up of the engine under all environmental

parameters.

Tolerance to dust the surrounding area. Because the

proposed engine - external combustion engine, the dust in the

air charge entering the combustion chamber from the surrounding

space, did not reach the crankcase and cylinders (in the engine

crankcase ventilation is not required).As a result, the engine no

additional abrasion of moving parts of drive mechanism.

In addition, because of the

low-speed air charge and exhaust gas in the regenerative heat

exchanger of a combustion chamber (heater air charge) and its

raspylivayuschem device, corrosion of these components is

negligible.

Dealing with short-term overloads. Motoresurs engine speed

is determined by the onset of creep limit of the material details of

the heater operating at high temperature.

With increasing pressure of gas in the inner cavities of the

engine speed limit creep increases.Nevertheless, short-term overload

associated with increased pressure of gas in the inner cavities,

slightly reduce the longevity of the engine, as well as details of

the heater temperature stays constant.

In general, any engine can be

guaranteed to withstand a short-term 50-80% integrated overload

without significant reduction in durability.

Heat in the cooling medium. Due to the availability of the

engine closed-loop system circulating the working medium heat almost

exclusively through the cooler, the heat should be possible

at lower temperatures.

Therefore the quantity of heat spent in the cooling water in the

engine at approximately 2 times higher than in internal combustion

engines, where the same effective performance. Therefore,

the size of the radiator cooling system of engines in vehicles

produced more than internal combustion engines of the same

destination .

In the

ship's engines, this feature is not a serious

shortcoming.

BASIC PARAMETERS Engines of 1500

cm 3

| NAME OF INDICATOR |

Ed.

amend. |

INDICATOR |

| Number of cylinders |

sh t |

8 |

|

Power |

l. c. |

124 |

| Number of turns |

of b / min |

3000 |

| Efficiency |

% |

52 |

| The coefficient of the progress of the

piston |

|

2.6 |

| The average gas pressure in the

cycle |

by HS / cm 2

|

32.0 |

| Displacement Cylinder |

with 3 m

|

1500 |

| The diameter of the engine

|

with m |

21.5 |

| The length of the engine |

with m |

64.5 |

| The content of CO |

g / km |

0,05-0,2 |

| Contents of C

x H in |

g / cm |

0,0015-0,009 |

| The contents of NO

x |

g / km |

0,1-0,2 |

| Weight of engine |

Ms. |

95 |

| Operating body |

|

Helium |

| Type |

|

Slant Pack |

| Location of cylinders |

|

Drum |

| Source of heat |

|

The

heat battery and mnogotoplivnaya the combustion

chamber |

| Assignment Engine |

|

The car and ship

|

Appearance PILOT MODEL

ENGINE

BASIC PARAMETERS OF

SETTLEMENT PILOT MODEL ENGINE

| NAME OF

INDICATOR |

Ed.

amend. |

INDICATOR |

| Number of cylinders |

pc. |

2 |

|

Power |

kW / hp. |

3.5/4.7 |

| Number of turns |

rpm |

1000 |

|

Efficiency |

% |

61 |

| The coefficient of the progress of the

piston |

|

4 |

| The maximum gas pressure

in the cycle |

atm. |

226 |

| Displacement Cylinder |

cm 3

|

100 |

| The diameter of the engine

|

mm |

89 |

| The length of the engine |

mm |

453 |

| The content of CO |

g / km |

0.05-0.2 |

| Contents of C

x H in |

g / cm |

0.0015-0.009 |

| The contents of NO

x |

g / km |

0.1-0.2 |

| Weight of engine |

kg |

7 |

| Operating body |

|

Carbon dioxide |

| Source of heat |

|

The

heat battery and mnogotoplivnaya the combustion

chamber |

"The engine with

the external leads heat.The patent number

2105156 dated June 23, 1995. RF.

"The engine with

the external leads heat.Patent number

2149275, dated 31 May 1999. RF.

|